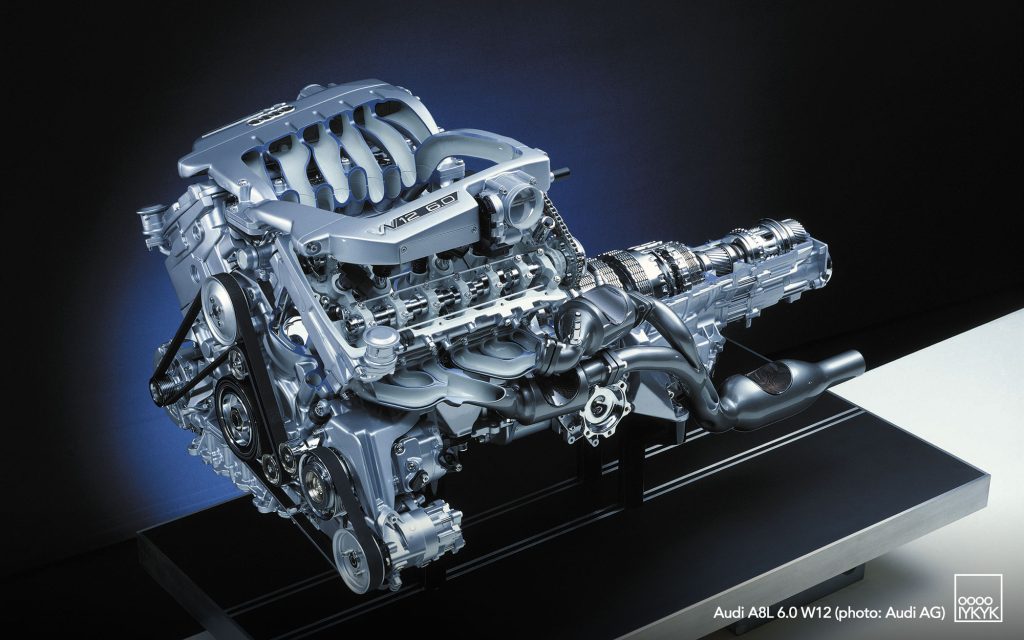

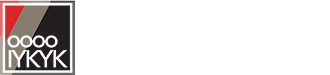

Manufacturer: Audi AG

Production: 2001, 2002

Engine family: AZC

Configuration: 6.0-liter W12, 48-valve (5,998cc)

Aspiration: naturally aspirated

Hybrid system: 48-volt MHEV plus (mild hybrid)

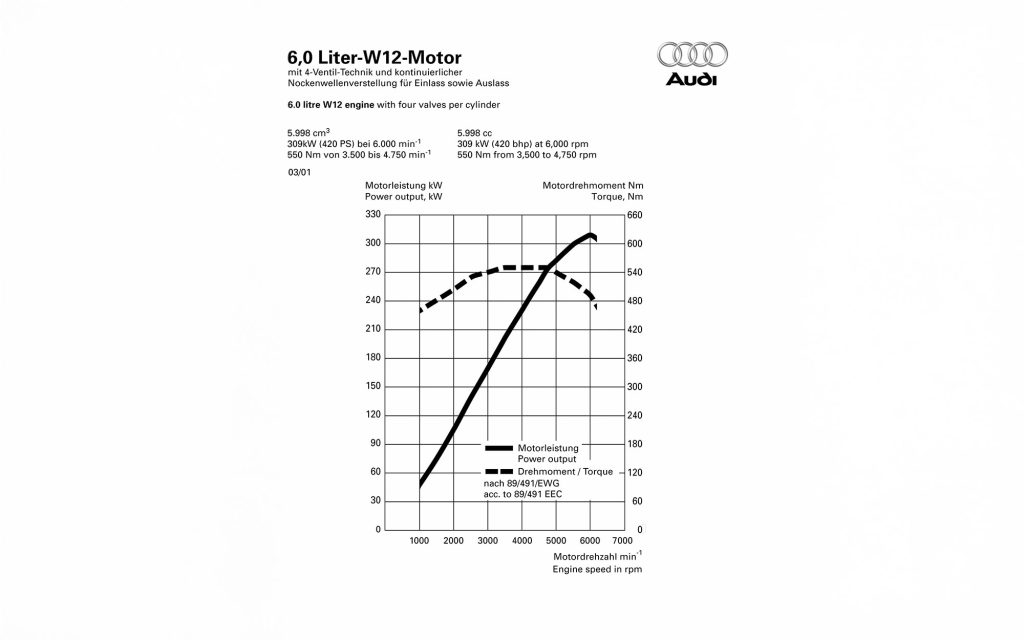

Output: 420 PS (309 kW; 414 hp)

Torque: 550 N⋅m (406 lbf⋅ft)

Applications: Audi A8L 6.0 quattro (D2, type 4D), Avus concept (1991), Volkswagen W12 concept (1998), Volkswagen W12 Spyder concept (1998), Volkswagen W12 Nardo concept (2001), Volkswagen Phaeton

SUMMARY

The Audi W12 engine coded AZC is the first production version of the Volkswagen–Audi Group’s twelve-cylinder W-configuration architecture, introduced for the 2001 model year in the Audi A8 (D2). Produced briefly between 2001 and 2002, the AZC engine represents the earliest and most technically distinctive iteration of the Group’s W12 family. Its compact layout, dry-sump lubrication, and intricate cooling and timing systems marked a major engineering milestone for Audi, allowing the marque to introduce its first series-production twelve-cylinder automobile. Although superseded by later evolutions of the W12 architecture, the AZC engine remains notable for its engineering ambition, rarity, and position in the lineage of high-performance Volkswagen–Audi Group engines.

ORIGINS & CONCEPTUAL BACKGROUND

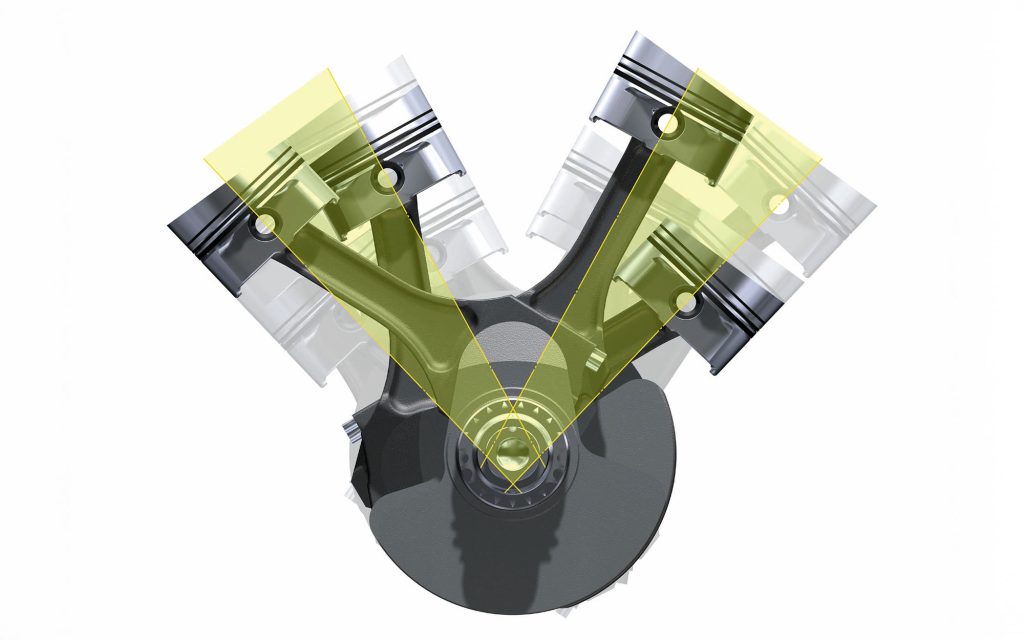

Audi first hinted at a twelve-cylinder engine in 1991 with the Avus quattro concept car, a polished-aluminum design study that featured a non-functional mockup of a unique W12-style fan engine. Although that early three-bank layout proved too complex for series production, it signaled a long-term interest in pursuing a compact, multi-cylinder flagship engine. Throughout the 1990s, the company continued experimenting with twelve-cylinder powertrain concepts, including several running prototypes. The decisive turning point came when Volkswagen engineers leveraged components from the narrow-angle VR6 engine family to develop a feasible, production-ready twelve-cylinder configuration.

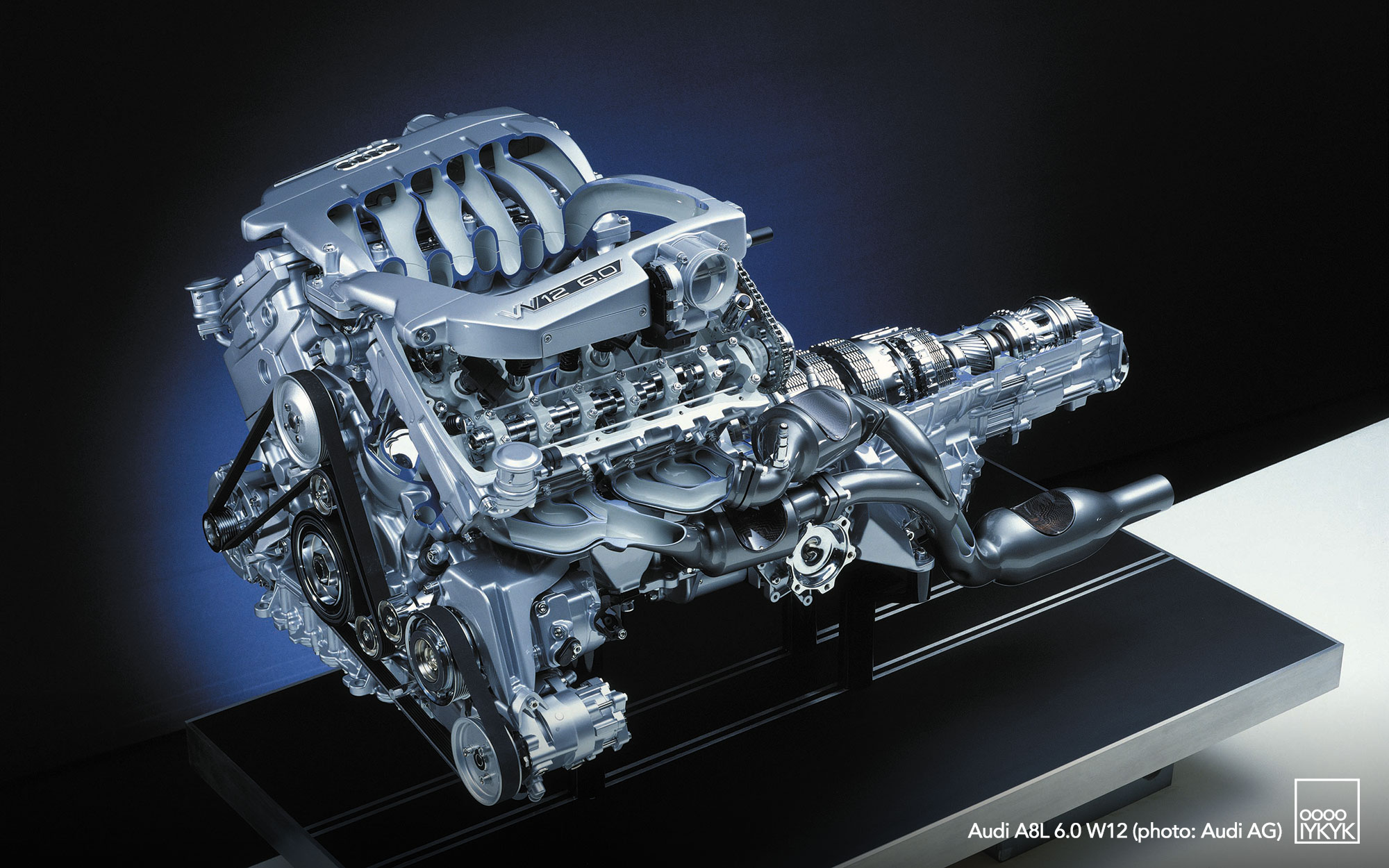

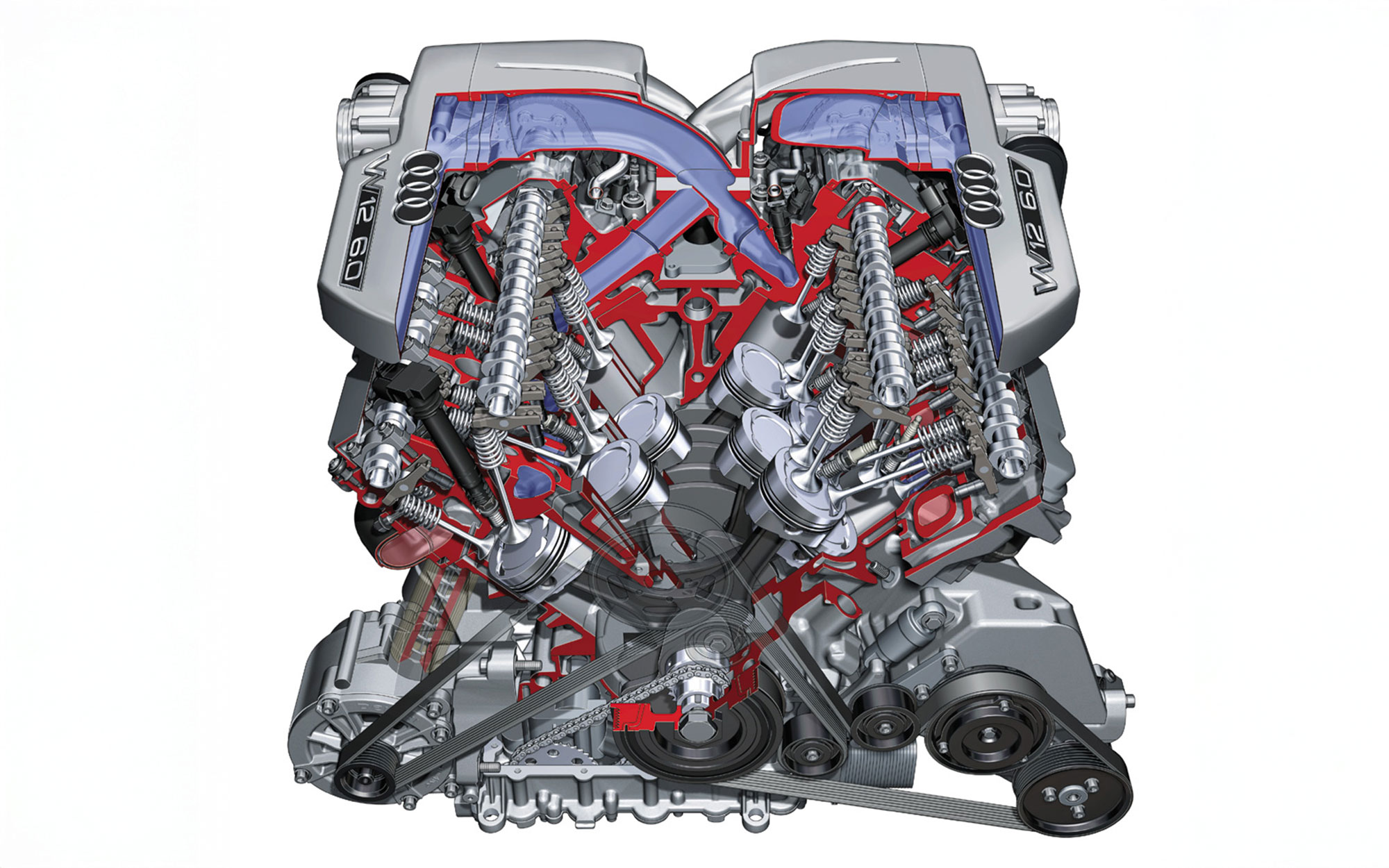

By configuring two 15-degree VR6 modules at a 72-degree angle, engineers created a compact twelve-cylinder unit with a footprint smaller than the company’s contemporary 4.2-liter V8. This approach allowed Volkswagen–Audi Group to package a twelve-cylinder engine longitudinally within existing architectures while maintaining the complexity, refinement, and performance expected of a flagship powertrain.

TECHNICAL ARCHITECTURE

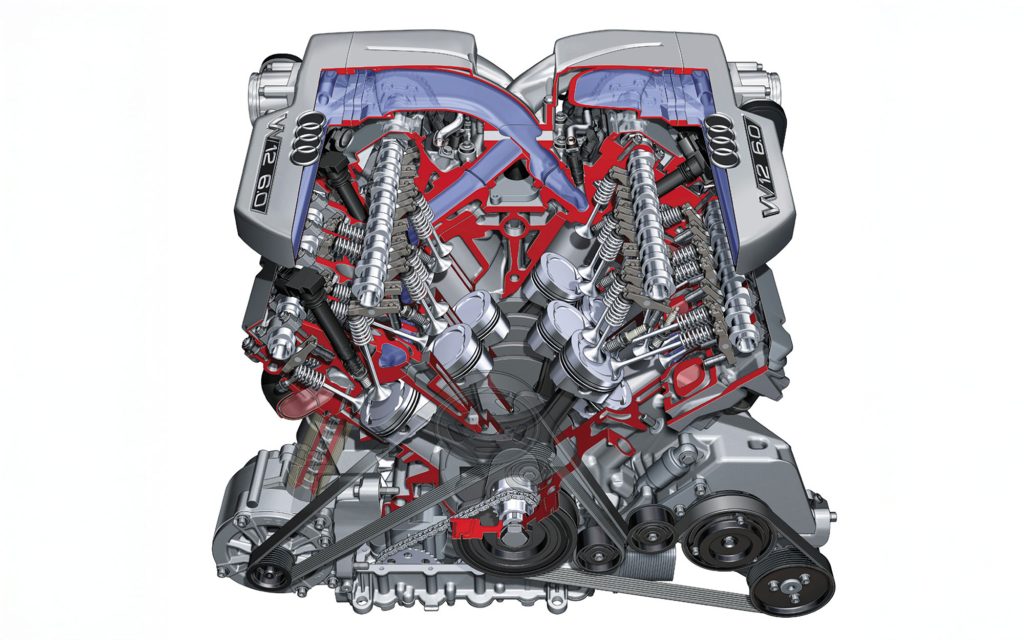

The AZC W12 displaces 5998 cm3 and produces 420 PS in its original specification. It uses an Alusil alloy block and a forged steel crankshaft with split crank pins, ensuring even firing intervals across the twelve cylinders. The engine comprises four sets of three cylinders arranged in two VR6-derived banks, each with its own pair of overhead camshafts. In total, the engine retains the same number of camshafts as a traditional V12 despite its unique geometry.

One of the most distinctive features of the AZC engine is its dry-sump lubrication system. It employs two scavenge pumps and a pressure pump driven by a shared sprocket through a chain drive at the front of the engine. All pumps are external gear units designed for durability and stable lubrication at high loads. Unlike many dry-sump systems of the period, the AZC design minimizes external plumbing, keeping most oil circulation within the sump assembly. This setup allowed the engine to sit lower in the chassis, aiding both packaging and handling while supporting continuous oil supply during sustained high-g operations.

The cooling system reflects the challenges of heat management in a tightly packaged twelve-cylinder engine. It pairs a conventional mechanical water pump with an auxiliary electric pump to maintain coolant flow during varying load conditions. The A8 W12 also features a hydraulic cooling fan system driven by a tandem pump shared with the power steering unit, supplemented by an independent electric fan. These layers of thermal control helped stabilize temperatures despite the compactness of the W12 layout.

The intake, exhaust, and valve-timing systems account for the engine’s asymmetrical geometry. Each cylinder bank contains two sub-banks, resulting in unequal runner lengths. Camshaft timing varies slightly between inner and outer cylinders to maintain consistent combustion behavior, and the AZC engine uses continuously variable valve timing on both intake and exhaust camshafts. The timing system employs a duplex primary chain driving an intermediary gear, which then drives each bank through simplex chains. Located at the rear of the engine, this system is known for its robustness and durability.

Contrary to popular belief, the W12 architecture does not use a balance shaft. Instead, electrically actuated engine mounts reduce residual vibration to achieve refinement comparable to a traditional V12.

EXHAUST & EMISSIONS SYSTEMS

The AZC engine incorporates four close-coupled catalytic converters that feed into two main converters downstream of the manifolds. Exhaust gases then pass through an X-pipe before entering a pair of silencers, with an exhaust flap fitted to one side for variable backpressure and enhanced acoustic tuning. The engine meets early-2000s Euro 3 emissions standards while maintaining high output for its displacement and configuration.

APPLICATIONS

The AZC engine debuted in the 2001 Audi A8 W12, marking Audi’s first production twelve-cylinder automobile. The model was offered exclusively with quattro all-wheel drive and an automatic transmission, available in both standard- and long-wheelbase configurations. At launch, it was considered the world’s most powerful twelve-cylinder luxury sedan. The engine served as the flagship of the first-generation A8 until production ended in 2002, after which later evolutions of the W12 appeared in the second-generation A8 and other Volkswagen–Audi Group vehicles, including Bentley’s Continental series and Volkswagen’s Phaeton and Touareg W12 models.

PRODUCTION & RARITY

Before reaching series production, engineers built 44 test vehicles in 2000 with varying 5.6- and 6.0-liter pre-production W12 iterations. The finalized AZC version entered the market in 2001 and remained in production for a limited period. Because the A8 W12 constituted only a small fraction of D2 A8 output, the AZC engine is rare today, especially in short-wheelbase form. Its dry-sump lubrication and early, intricate component design set it apart from later, more conventional wet-sump W12 engines, making it of particular interest to collectors and engineering enthusiasts.

LEGACY

The AZC W12 occupies a unique place in Audi history. As the company’s first production twelve-cylinder engine, it demonstrated the feasibility of packaging high-capacity performance in a compact form compatible with the brand’s all-aluminum Audi Space Frame platform. It also laid the foundation for a family of W-configuration engines that would go on to power high-performance and ultra-luxury cars across multiple Volkswagen–Audi Group marques.

Though later W12 engines refined and simplified aspects of the design, the AZC remains the most technically ambitious version, distinguished by its dry-sump configuration, advanced thermal management and intricate timing architecture. Today it is recognized as a landmark in the evolution of German high-displacement engines and a defining technical achievement of the early 2000s Audi engineering program.

REFERENCES

Volkswagen Group W12 Engine – Wikipedia

Three Stages of the VW-Audi NA W12 Engine – DRJLT.com

PHOTO GALLERY