What: Audi Al2 concept

Model Family: A2 (type 8Z)

Debuted: 1997 Frankfurt IAA, Frankfurt, Germany

Year: 1997

Number Produced: 1

Model / Generation Code(s): type 8Z

Chassis / Matrix: A04, PQ24

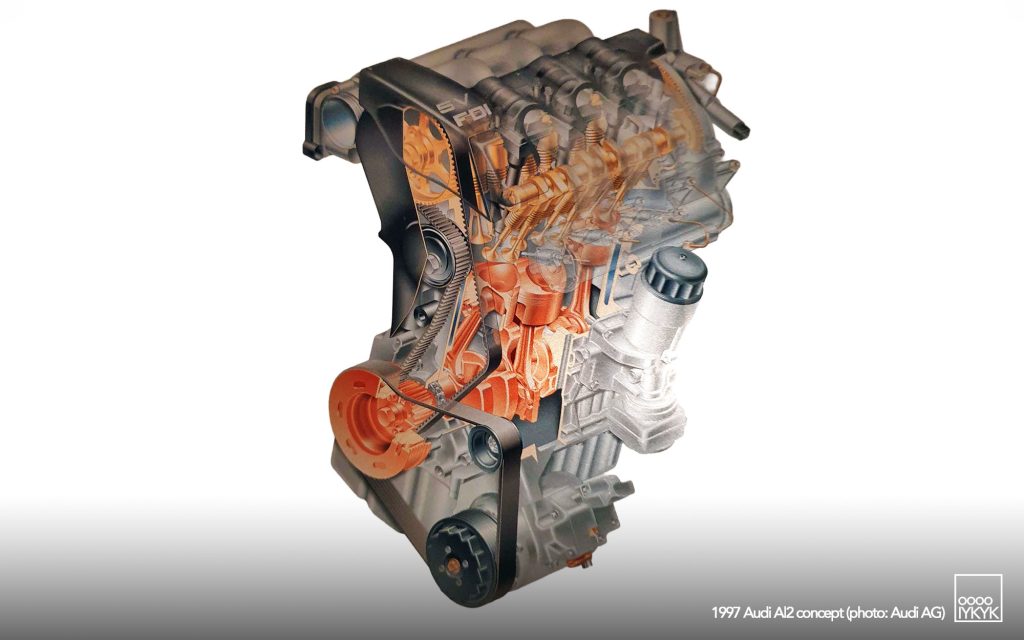

Engine: 1.2-liter 3-cylinder FSI

Transmission: 5-speed manual

Power: 75 bhp at 5500 rpm

Peak Torque: 115 Nm at 3000 rpm

Acceleration (0-100 km / 62 mph: < 12 seconds

RELATED

Concept Cars: Al2 Open End, “Ringo” Prototype, A2 -etron

Road Cars: A2 (type 8Z)

Race Cars: none

SUMMARY

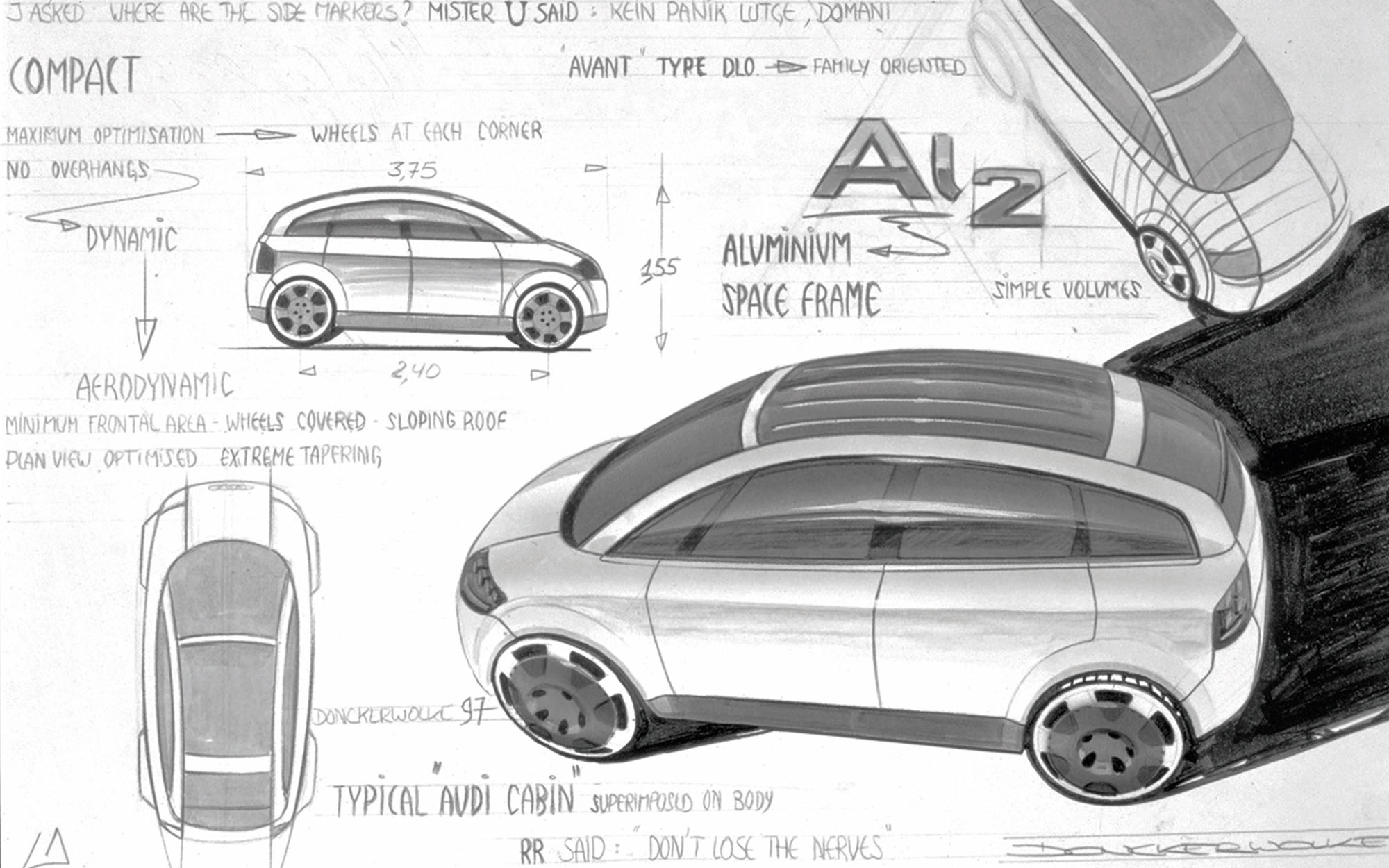

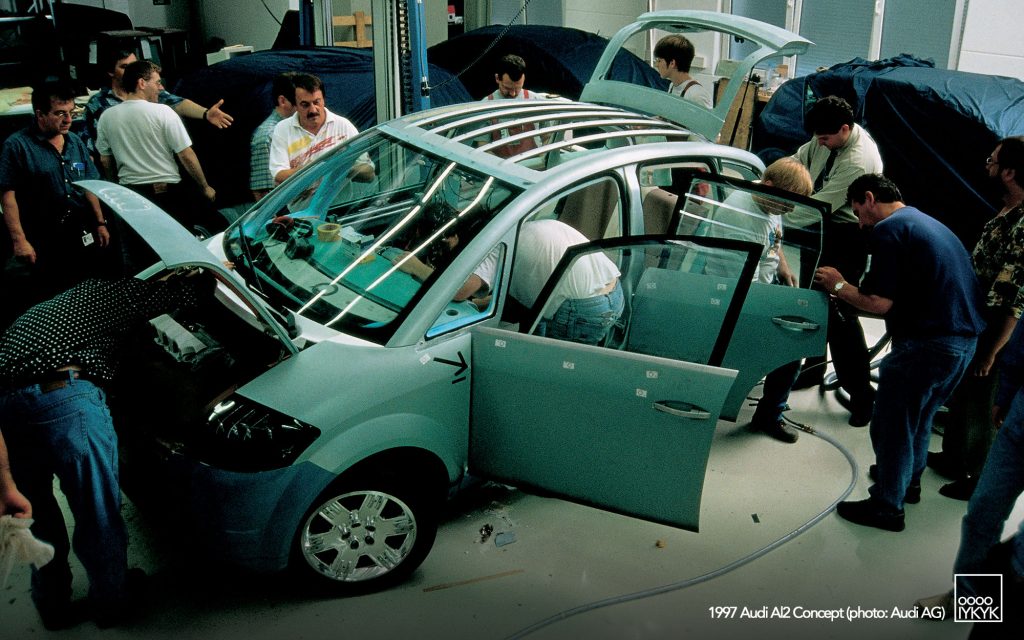

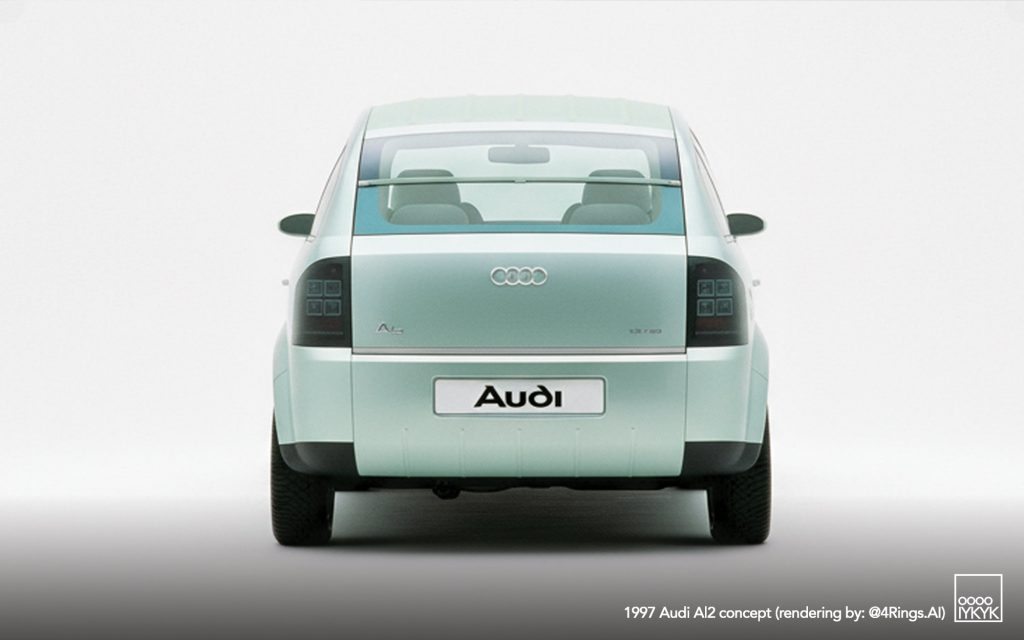

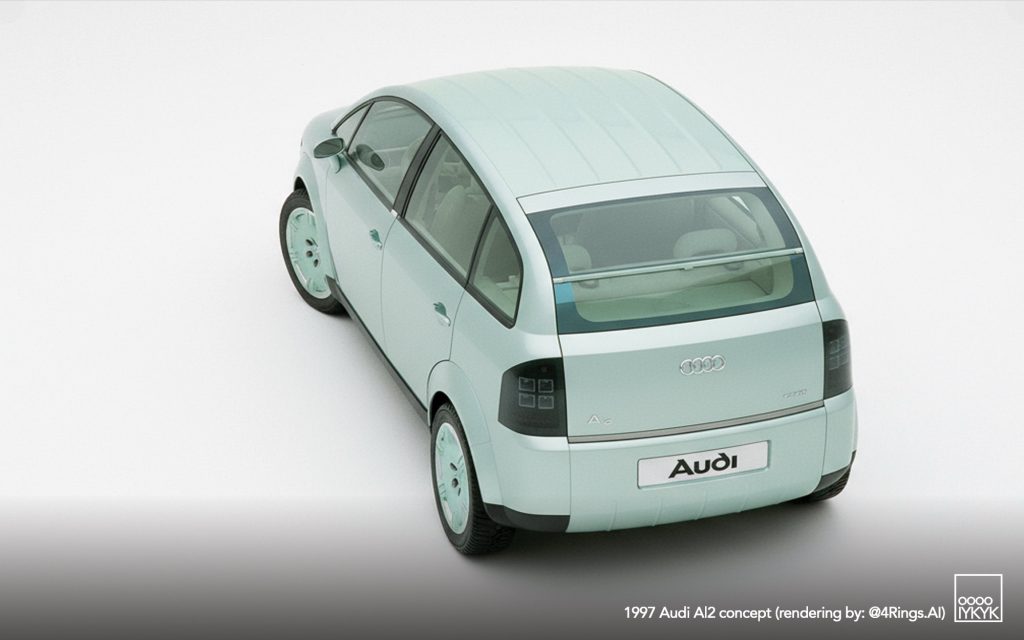

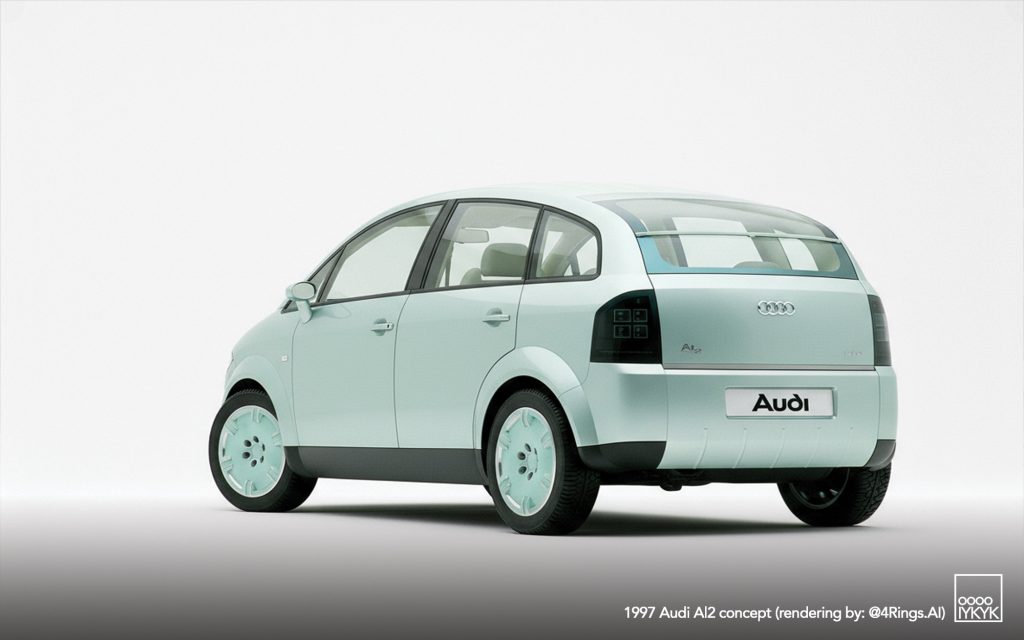

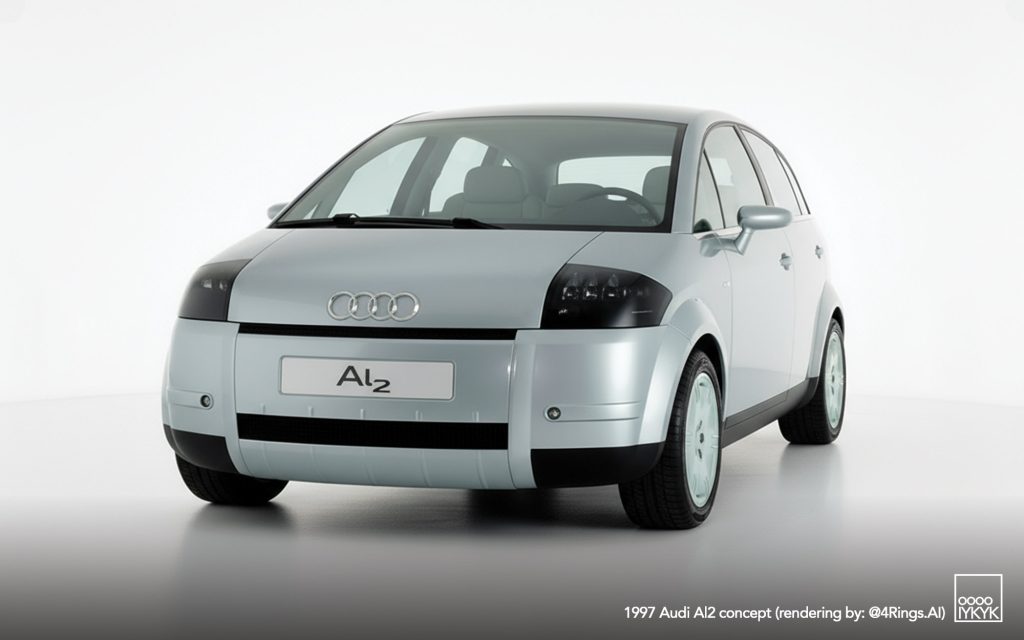

The Audi Al2 was a concept car presented by Audi at the 1997 Frankfurt International Motor Show (IAA). It served as a direct precursor to the production Audi A2, which entered production in 1999. The study was internally nicknamed “Light Green” due to its paint finish, and is one of several prototypes that explored lightweight construction and advanced efficiency technologies in the late 1990s.

DESIGN & DEVELOPMENT

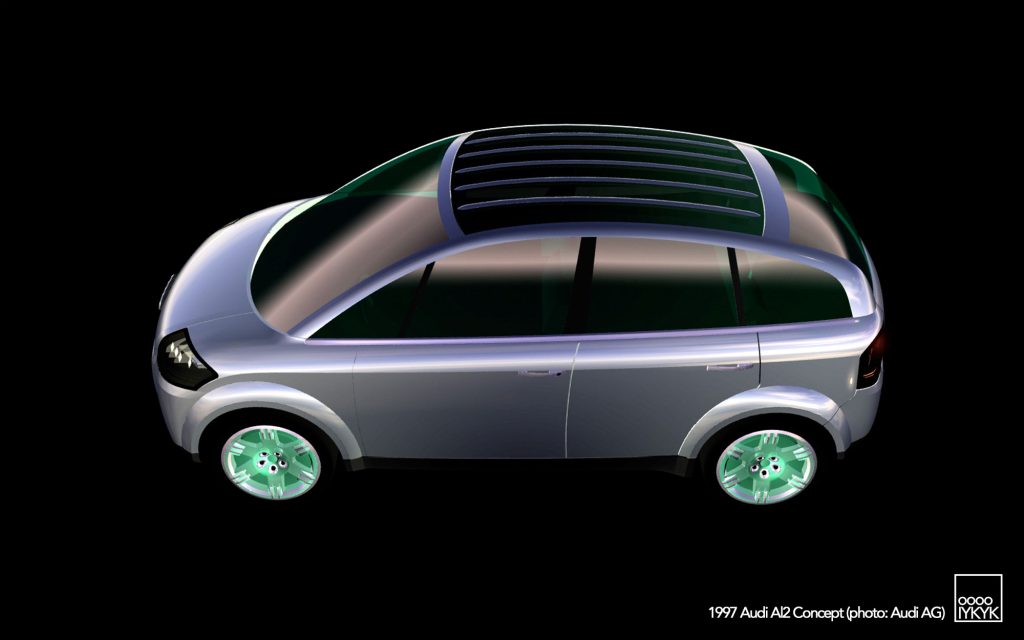

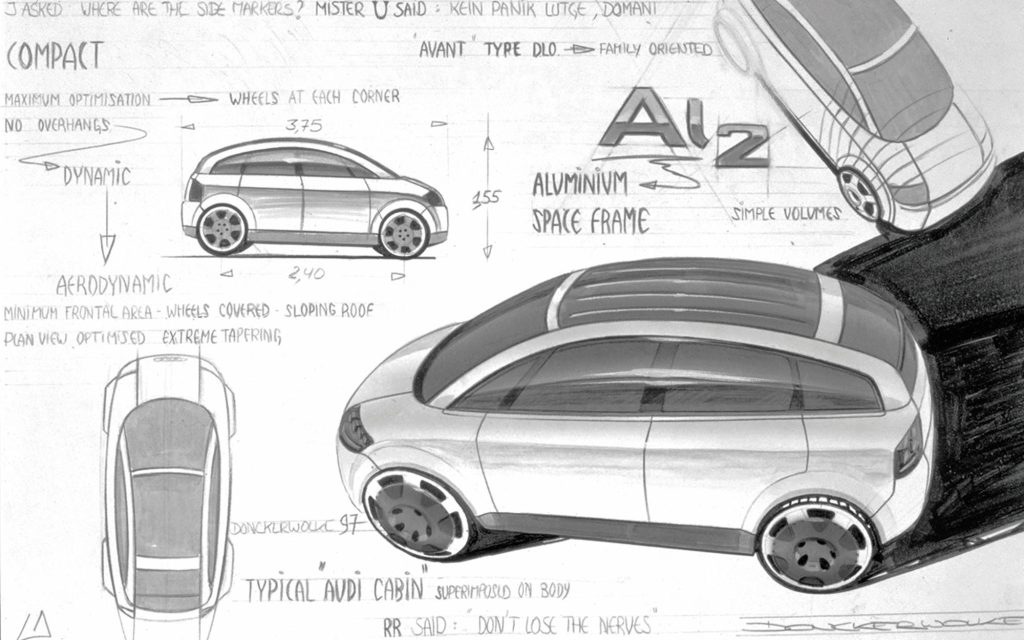

The Al2’s design was overseen by notable Audi figures of the era. Luc Donckerwolke, working with Gerhard Pfefferle, led the exterior design, while the interior was directed by Stefan Sielaff. The vehicle adopted compact exterior dimensions—3.76 m long and 1.56 m high—but pursued a “tall and flat” design philosophy, utilizing a sandwich floor and elevated seating to maximize interior space for four occupants.

A distinguishing feature of the study was its transparent plastic roof, reinforced by five illuminated aluminum struts constructed according to the stringer principle. This provided both structural strength and a bright, airy cabin environment.

TECHNICAL INNOVATIONS

The Al2 was built using the second-generation Audi Space Frame (ASF) technology, derived from the flagship A8. This aluminum-intensive construction allowed the concept to achieve a base weight of 750 kg (810 kg in fully equipped form), approximately 250 kg lighter than a comparable steel-bodied vehicle.

The powertrain introduced Audi’s early exploration of direct fuel injection (FDI) for gasoline engines. The concept employed a 1.2-liter three-cylinder direct-injection spark-ignition unit, producing 55 kW (75 hp). Despite its modest size, the engine was capable of 0–100 km/h in under 12 seconds and a top speed exceeding 170 km/h. Combined with the lightweight ASF body, low drag coefficient, optimized rolling resistance, and an automated manual transmission, the Al2 demonstrated fuel consumption around 40 percent lower than conventional vehicles of comparable size and performance.

EQUIPMENT & TECHNOLOGY

The Al2 also incorporated advanced features that anticipated future production technologies. These included:

- Automatic distance control

- Photo-electric sensors enabling non-touch opening of compartments and lids

- A multifunction steering wheel controlling navigation, audio, telephone, and climate systems without requiring the driver to remove hands from the wheel

According to Dr. Mischke, then Board Member for Technical Development at Audi AG, the Al2 demonstrated the company’s aim of combining “very high standards of driving enjoyment, comfort and safety” with resource efficiency for the 21st century.

AERODYNAMIC DEVELOPMENT

Aerodynamics played a central role in the Al2 project. As project manager Harald Wester later noted:

“Yes – it was clear to all of us from the beginning! The car had to be optimally streamlined. We practically slept in the wind tunnel to achieve optimal aerodynamics.”

PRODUCTION LEGACY

The Audi board approved production of the A2 in late 1997, and the final production model was unveiled at the 1999 Frankfurt IAA. While sales were limited, the Al2 concept and subsequent A2 production model remain historically significant for their pioneering use of aluminum construction, efficiency-focused design, and early application of direct fuel injection technology in a spark-ignition engine.

SEE ALSO

- Audi A2 (1999–2005)

- Audi A2 “Ringo” prototype (1995)

- Audi Al2 Open End concept (1997)

- Audi A2 concept (2011)

- Audi AI:ME concept (2019)

- Audi A2 e-tron (2025 anniversary concept)

PHOTO GALLERY

PRESS RELEASE

The Audi Al2 design study: Fascinating technology, graceful charm

[source: Audi AG, Sept 8, 1997]

Short version

A glimpse into the future:

The Audi Al2 design study with FDI direct fuel injection

Aluminium technology, direct fuel injection, an automated manual gearbox, ample space, acceptable standards of performance – in fact, everything that the car of the future needs.

The Al design study is a fascinating blend of passion and commonsense. This car, incorporating technology that is already established, is Audi’s vision of a high-efficiency car which takes up little space on the road, yet affords ample interior space for four adults. This car provides an intriguing foretaste of the car of the future, revealing all the essential traits of a concept geared entirely towards the new millennium: fascinating technology with ease of movement.

The comprehensively new Al2 is only 3.76 metres long but stands 1.56 metres high, embracing a “tall and flat” plateau concept. With its high-level seats and a sandwich floor, the available space is put to excellent use.

The general underlying concept of this design study is to demonstrate how well graceful charm and effortless mobility can be reconciled. This is illustrated particularly well by the transparent plastic roof built according to the stringer principle. There are five illuminated, load-bearing aluminium struts, or stringers, running lengthways, creating a uniquely light-filled, airy atmosphere. The Al’s transparency adds a new dimension to ease of movement, preparing a feast for the senses.

The aluminium body is built according to the principle established with the Audi A8’s ASF Audi Space Frame. The second-generation ASF used in this instance combines outstanding rigidity and crash strength with an extensive range of comfort and safety equipment, resulting in an overall vehicle weight of only 750 kg for the basic version. The design study that is on show, complete with all its equipment options, weighs 810 kg. This is about 250 kg less than if it had been built with a conventional steel body.

The Audi FDI (Fuel Direct Injection), a technology study with three cylinders and the world’s first direct-injection spark-ignition engine, is being demonstrated on the Al. With a displacement of 1.2 litres, this engine develops an output of 55 kW (75 bhp). Despite its nominally small capacity, the direct-injection spark-ignition engine is easily capable of excellent performance (0-100 km/h in less than 12 seconds / top speed in excess of 170 km/h) and also makes for pleasurable driving. In conjunction with the ASF body, the very low drag coefficient, reduced rolling resistance and the automated manual gearbox, the Al, design study achieves fuel consumption that is on average around 40 percent lower than a conventional vehicle offering the same amount of space and with comparable engine performance.

This new interpretation of ease of movement is further enhanced by such high-tech equipment features as automatic distance control and non-touch opening of lids and compartments by means of photo-electric sensors. The multifunction steering wheel allows the audio, navigation and telephone systems, together with the air conditioning, to be operated without the need for the driver to lift his hands off the wheel.

“Our Audi Al2 demonstrates that very high standards of driving enjoyment, comfort and safety will still be fully compatible with the responsible use of natural resources in the 21st century,” commented Dr. Mischke, AUDI AG Board Member for Technical Development.

A vehicle for innovation:

The general concept of the Audi Al, design study

The future is not already predefined. It is what we make it. What will the car of the future be like? It should ideally occupy little road space, but also ought to be spacious, safe, economical and comfortable. Obviously the overall concept must show a responsible attitude towards both the people who drive it and the environment in which it is driven. And it should of course be enjoyable to drive.

More than simply tolerating it, people should come to like and desire it.

The Audi Alz aims to thrill: here is a fascinating technical concept that opens up new dimensions in ease of movement. It is a manifestation of creativity and custom design, with the ability to resolve conflicting requirements. Safety and lightweight design, driving enjoyment and low consumption, occupant comfort and low weight, high performance and ample space. Demonstrating that there is still ample scope for surprise in car design, we believe its technical concept speaks for itself, as a prime example of “Vorsprung durch Technik”. The following features are making their first appearance on the Audi Alz:

- The second-generation ASF Audi Space Frame is the next stage in the evolution of aluminium technology. This time, the concept is based on our own Audi A8 Space Frame concept. Hence the design study’s name: “Al” is the chemical symbol for aluminium, and “2” indicates that this is the second Audi to incorporate this technology. Another skill learned from Audi’s large model is the art of saving weight: the full-equipment version being exhibited has an overall weight of 810 kg, with the basic version weighing in at 750 kg.

- The world’s first three-cylinder direct-injection spark-ignition engine with five-valve technology. Displacement: 1.2 litres. Output: 55 kW (75 bhp). A new concept for the engine, too. Audi’s engineers have made use of their experience in direct-injection engines for handling the high fuel injection pressures encountered here. In this case, the resulting fuel consumption is between 15 and 20 percent lower than that of a conventional spark-ignition engine.

- The vehicle is designed as a plateau concept with double floor. Despite the compact overall length of only 3.76 metres, front and rear occupants alike have an impressive amount of seating space. In addition, there are side airbags in the front backrests and head airbags integrated into the roof posts for all occupants.

- There are also numerous technical innovations and ingenious details such as automatic distance control, emergency-call and navigation system, photoelectric sensors for contactless opening and many other imaginative equipment features.

- An automated manual gearbox with tiptronic: the high efficiency and low weight of a manual-shift five-speed manual gearbox are combined with the convenience of an automatic clutch. Here is a compact car with a low-effort automatic feature that enhances driving enjoyment – and an economical manual gearbox that is made for operator convenience.

The Audi Al2 has the capacity to perform more efficiently, while needing fewer natural resources and using up less energy. Knowing which is the best material to use is vital to this concept. Its combination of low weight and efficient technology represents a radical shift in emphasis in automotive concepts:

Its fuel consumption undercuts that of an equivalent compact car with conventional body design and spark-ignition engine by as much as 40 percent.

In fact, only a small car with diesel engine comes anywhere near it for fuel economy. Yet it still develops a respectable 55 kW (75 bhp), an output which could previously only be achieved by a conventional compact-class car with a much larger engine. The Al accelerates from 0 to 100 km/h in less than 12 seconds, achieves a top speed of over 170 km/h and demonstrates very good flexibility for a car of this class, thanks to its 115 Nm engine torque at 3,000 rpm. These advantages are coupled with its spacious interior, upmarket equipment and the standards of safety that are expected of an Audi. The result is a new dimension in ease of movement, coupled with a responsible attitude.

Effortless mobility is combined with a generous helping of enjoyment.

The future of the compact class is presented in a refreshingly appealing light, as manifested by the design of the Al2.

Design

Air, light and ease of movement

As you look inside this car, your eyes are immediately drawn to a transparent plastic roof of a light green colour. The material is reminiscent of frosted glass.

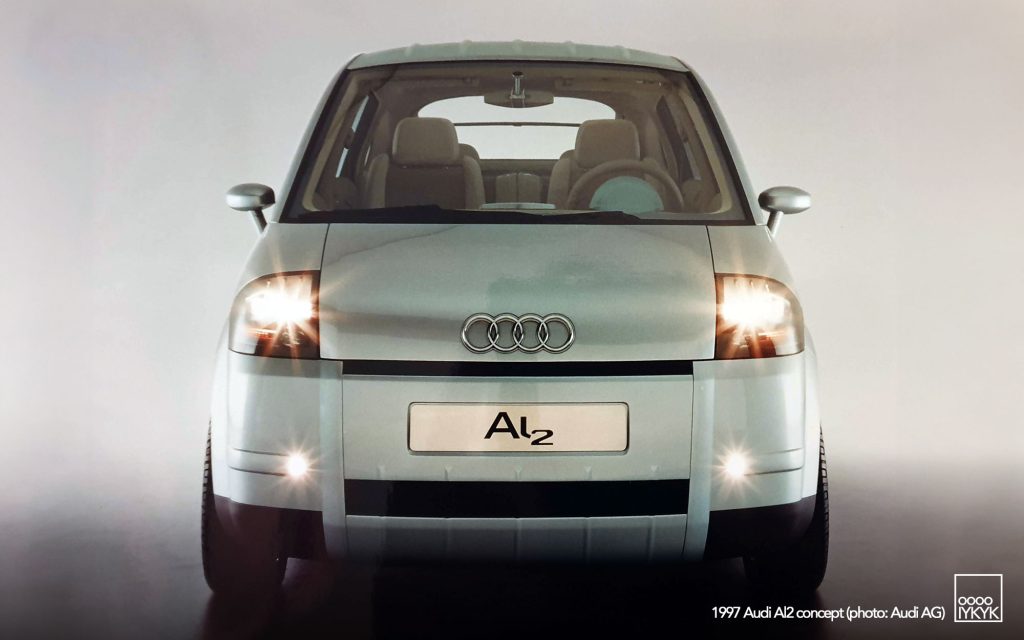

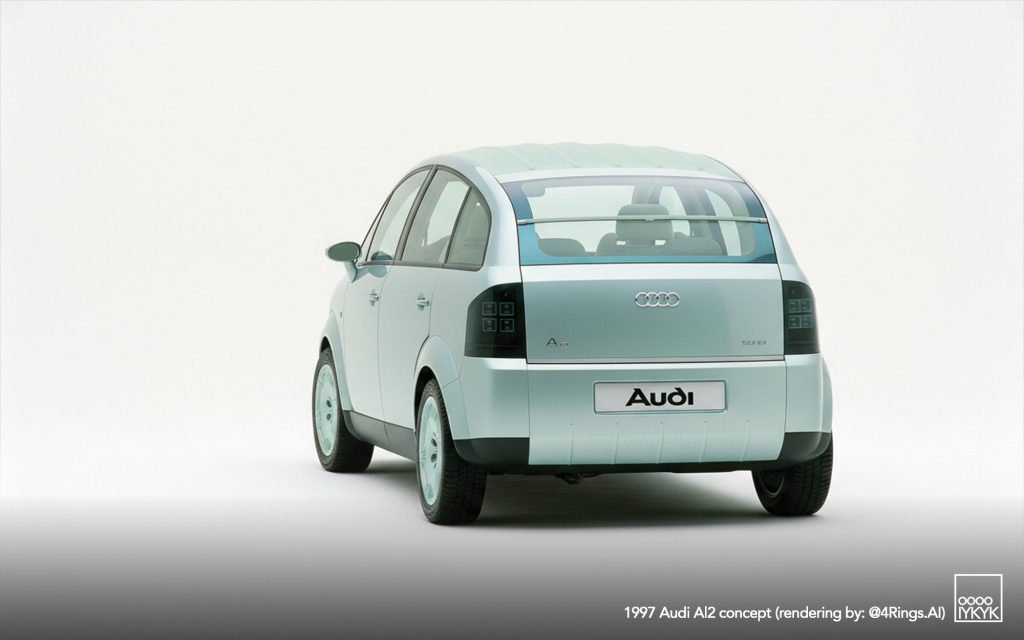

The overall impression is one of open horizons. Five stringers, supporting longitudinal members of light alloy, serve to divide up the transparent roof element visually. It is easy to find allusions to the curved light alloy struts of the Zeppelin airship, a shining example of expert light-weight design. The taut outer skin of the Audi Al2, with its expansive surfaces and shape which produce the outstanding drag coefficient 0.25, is a throwback to the aesthetics of this early form of air travel. It is the logical progression from the formal idiom already established by the Audi TT and the new A6, as if this were the most natural thing in the world.

At the front end, the bar-design headlights are a striking expression of the high-tech concept within: a single light source positioned at one side “beams” a ray of light through a system of preliminary lenses and light guides to four headlight lenses. The new design is shorter and lighter, and illuminates the road surface more effectively.

The side view of the Al2 is characterized by the long wheelbase, Audi’s typical side window design and the back, which gently rises high above the interior. At the rear, a narrow spoiler above the rear window assures good aerodynamics.

Its integral light strip also accommodates the third brake light.

Its graceful aesthetic appearance is completed by the most minute of detail features, such as the aluminium fuel cap or the transparent wheel covers of light green plastic. The same is true of the interior, which is visionary in more than one sense. Narrow halogen lights are incorporated into the five roof stringers, creating the luxurious, airy atmosphere of a spacious domed roof at night time.

The recessed door handles, centre console and shifting gate seemingly float in space. Even the seats and backrests are made of a semi-transparent fibre material which allows light and air to permeate.

The Al2’s transparency adds a new dimension to ease of movement, preparing a feast for the senses.

The high-tech material aluminium and the transparent plastics are combined with beige and sand coloured natural fabrics and fibres. The harmony of nature and technology is even symbolized by the honeycomb pattern of the air outlets and radiator grilles. Lightweight design, bionics, new horizons: the compact car of the future, made for people.

ASF lightweight design:

In the family

The challenge to the developers of the Audi A8 was to create a premium large-size car weighing no more than a deluxe midsize car. The international acclaim which the A8 has enjoyed aptly confirms how resoundingly successful its developers were. The challenge for the Audi Al2 design study was equally exacting: to create a car that is enjoyable to drive, while equipped in every respect for the next millennium. Our aim was to develop an extremely environment-friendly car with standards of occupant comfort and safety in keeping with those set by Audi on its established models, and which would also provide a high degree of driving enjoyment. The above challenges represent two sides of the same coin, but the underlying principle for each model was the same: to reverse the trend towards increasing vehicle weight. Consequently, the technical solution adopted was identical in both cases: the all-aluminium body featuring ASF Audi Space Frame technology.

Audi integrates large, load-bearing aluminium panels into a high-strength aluminium frame structure. The space frame proper consists of extruded sections joined together by means of vacuum diecast nodes. Having acquired four years of experience in building the Audi A8, the body specialists have now produced a second-generation space frame: thanks to optimized production methods, the number of cast nodes has been reduced on the Al2. Optimized joining techniques now allow most of these nodes to be produced by butt-welding the extruded sections. As a result of “internal high-pressure reshaping”, the number of bending and cutting operations required has also been drastically reduced. The second-generation Audi Space Frame is consequently even lighter than its predecessor and, in combination with the plateau concept, is also more rigid.

In conjunction with the systematic weight optimization of all its assemblies, the gross weight of the Alz is a mere 750 kg, or 810 kg with the full equipment range being demonstrated. This, combined with the efficient engine, is the key to Al’s surprisingly low fuel consumption. It represents a completely new, pioneering departure in the race to develop ecologically acceptable cars of the future – following the precedent set by its older brother, the Audi A8.

Space and transparency:

The only way is up

When space is at a premium, people build skywards – as is adequately demonstrated by the skyscrapers of New York and Tokyo. Since road surface in our conurbations is likewise becoming increasingly scarce, the exterior dimensions of cars will gradually decrease. However, consumers are unlikely to tolerate restrictions in the amount of interior space available. Here, too, the solution is to “build skywards”: the Al2 is based on a sandwich-construction plateau concept. Its roof stands 1557mm above ground level – two hands higher than a conventional saloon car. This design provides the driver with an excellent view of the road ahead, and also accommodates four adults in a relaxed and comfortable seated position.

The vehicle’s potential interior space is exploited to the full, thanks to the long wheelbase of 2406 mm. The vehicle measures 3765mm by 1620 mm. Knee, elbow and head room in the Al2 are quite outstanding for a car of this size. The transparent, light-filled interior accentuates this feeling of spaciousness even further.

The payload is 425 kg, and the luggage compartment has a capacity of 350 litres. There is a separate section to the luggage compartment, concealed beneath the floor, accommodating a special, tailormade set of cases for maximum utilization of the available space. The main section of the luggage compartment can be enlarged in the familiar way, by folding down the rear seat to form a single load area extending right up to the front seats. The result is a luggage area with a capacity of 840 litres, without even including the underfloor compartment.

Safety:

The principle of prevention

The high-strength frame structure of the Audi Space Frame acts as a kind of protective cage. The occupant cell is appreciably more rigid than that of comparable steel-bodied vehicles, affording excellent protection for occupants.

The plateau concept with the high-level seats, combined with the dual-floor structure, plays a vital role in this. Crash tests have confirmed that the ASF concept is highly rigid and dimensionally stable. The generous crush zones have a high energy-absorbing capacity upon impact. If the car is hit side-on by another vehicle, the raised seating position and the high continuous-cast sill are an added advantage.

The two front airbags in the backrests are complemented by side airbags in the roof posts, otherwise known as inflatable curtains, which reduce the risk of head injuries to both front and rear passengers in the event of a side-on collision.

When an airbag is inflated, an automatic emergency-call signal is simultaneously triggered off. The vehicle’s position can be identified via the navigation facility’s GPS Global Positioning System. The control centre notifies the nearest rescue services, and contact can be established with the occupants via the hands-free facility of the telephone. An ambulance and the police can then be summoned to the scene of the accident if appropriate. This function can also be cancelled manually.

Existing constellations of vehicle weight, size and safety will have to be rethought as a result of Audi’s pioneering study, because in virtually all types of accident the Alz provides a standard of occupant safety that has previously only been available on much bulkier, heavier vehicles.

Its standards of active safety, already exemplary, are further enhanced by the Automatic Distance Control (ADC) system, an electronic distance warning device. The vehicles in front are automatically registered by radar. This system represents the latest component of the cruise control system. It is now possible to maintain both a constant, preselected speed with the Al and a defined distance from the vehicle in front. As the ADC is intended purely as a convenience feature, and not as a safety system (e.g. to prevent nose-to-tail collisions), it adopts a softly-softly approach in maintaining the necessary distance: first the throttle is closed down, then the brakes are applied gently if necessary. In other words, if the driver suddenly encounters the end of a tailback, full concentration and a swift response are still called for. As on the cruise control system, it can be deactivated simply by touching the accelerator or footbrake. The nerve centre of the Automatic Distance Control is a radar unit incorporated into the bumper. This principle is more accurate than other systems, has a range of up to 150 metres and reliably detects vehicles on the road ahead even in poor weather conditions.

The system is intended primarily for use on motorways or fast roads, and is of greatest benefit to the driver here by virtue of its added convenience; however, it also generally harmonizes the traffic flow and helps the environment by reducing fuel consumption.

Equipment:

Open Sesame!

Imagine simply reaching for the glove box and seeing its lid gently glide open.

This is no longer wishful thinking: the Al2 almost appears to read the driver’s mind. Photo-electric cells control these opening functions, which oblige with almost uncanny precision. The mobile phone compartment and ashtray are likewise activated by this contactless principle and opened by electric motors.

The navigation system’s monitor is also switched on at the driver’s behest.

This car is always glad to oblige: the multifunction steering wheel allows the audio, navigation and telephone systems, together with the air conditioning, to be operated without the need for the driver to lift his hands off the wheel. The navigation system’s monitor can also receive television pictures, for entertaining interludes.

Its family-friendly approach is all part of the service: there is a picnic basket in a design that matches the interior, complete with folding table. Removing the child’s seat is now astonishingly simple, thanks to the ISOFIX seat mounting system. Once removed, it fits neatly inside a lightweight but sturdy pushchair with titanium frame. When the younger passengers begin to get restless during a long journey, they can simply mount an electronic toy box between the front seats and operate it via remote controls connected up by cables.

As soon as the car is unlocked via the radio remote control, and for approximately 20 seconds after it has been locked, the inside light, headlights and rear lights come on to help passengers get into the Al2 at night time, or find their way to the front door after arriving home. This feature also ensures that the vehicle’s surrounding area is conveniently and reliably illuminated.

In the future, a car’s premium claim will depend on more factors than simply its size or engine output. The Al2 proves that even a highly economical, compact vehicle can provide superlative standards of comfort, safety and quality.

FDI: the Audi Fuel Direct Injection engine

Unleashing energy from a mere droplet of fuel

Chaos reigns inside the combustion chamber when the mixture of fuel and air is ignited and combusted. Dozens of mixture components are oxidized and reduced in hundreds of different chemical reactions. The pressure and temperature fluctuates wildly within a fraction of a second. Harnessing the physical and chemical reactions amid such apparent pandemonium is the main challenge facing the engineer. Those who succeed in mastering these complex processes will be richly rewarded, with efficient engines the fruit of their labour.

Audi has already made a quantum leap in the field of diesel engines. Its engine developers pioneered and refined the direct injection principle, bringing the TDI concept to maturity in 1989 and heralding in a new era in fuel economy. The temptation to transfer this technical expertise to spark-ignition engines eventually proved too strong to resist. As a consequence, the Audi Al now has the world’s first direct-injection spark-ignition engine, a technology study with three cylinders. The application of the direct-injection principle to a spark-ignition engine meant that different operating conditions had to be accommodated; in this instance, the fuel/air mixture should only combust when ignited at a precise moment by a spark plug, and not spontaneously, as is the case with diesel fuel.

In the Audi FDI (Fuel Direct Injection) engine, one injector per cylinder forces the fuel directly into the combustion chamber, at a pressure of up to 100 bar, whereas the conventional fuel injection concept involves injecting the fuel into the intake port at only 3 to 4 bar. Depending on its momentary operating status, the combustion chamber is filled via three inlet valves and their corresponding intake ports according to an ingenious system of variable charging movements.

A stratified charge is established in the working chamber by means of air swirling. The air and fuel strata in the combustion chamber must be arranged in such a way that a cloud of combustible mixture surrounds the spark plug; for reasons of efficiency, the further away from the spark plug, the leaner the mixture should be. At part load, even a minute droplet of fuel is adequate for the combustion process to take place. Whereas the mixture normally comprises one part fuel to around 14 parts air, the direct-injection engine can run on a mixture with one part fuel to 40 or more parts air. In other words, the engine can operate on an extremely lean mixture that makes for low consumption.

Thanks to the FDI concept, Audi’s engine development specialists have succeeded in bringing down fuel consumption at part load by an average of between 15 and 20 percent compared with a conventional spark-ignition engine.

At or close to idle speed, the gain in fuel economy may be even greater.

Mastering the technology of a spark-ignition direct-injection engine is a science that necessitates meticulous accuracy. The exhaust emissions in particular require considerable attention and complex technology, as conventional three-way catalytic converters are no longer capable of operating ideally beyond a lambda value of 1 (the stoichiometric mixture of one part fuel to approximately 14 parts by weight air). Additional newly developed catalytic converter systems are essential for reducing the nitrogen oxides in particular when outside the operating range of conventional 3-way catalytic converters.

Audi’s engine specialists have investigated various concepts involving both the combustion chamber’s geometry and the combustion process itself, together with various forms of exhaust gas treatment. The combination of a 3-way catalytic converter and a supplementary DeNOx catalytic converter helps the Audi FDI to satisfy the forthcoming European exhaust emission standards.

Three-cylinder concept:

The art of elimination

We were looking for a very low-consumption spark-ignition engine to power this compact vehicle, and tests confirmed that a three-cylinder version with a displacement of 1.2 litres was ideal. Each cylinder consequently has a capacity of 400 cm”. Above all, the three-cylinder unit’s relatively large bore of 81 mm (stroke 77.4 mm) is compatible with the specific combustion chamber design that is essential to the direct-injection concept. Audi was also able to retain its tried-and-tested five-valve technology, with three inlet and two exhaust valves.

This concept brings benefits for cylinder charging, and thus also for the engine’s torque pattern, performance and emissions.

Compared with a four-cylinder engine of the same displacement, the three-cylinder version is superior in terms of thermodynamics (less thermal loss), friction, weight and the number of moving parts. The consistent use of lightweight design and the aluminium crankcase have brought down its weight even further, creating a power unit that is unique for its class.

Even at low engine speeds, the three-cylinder engine develops relatively high torque for an engine of this size (115 Nm at 3,000 pm). This, together with a more than adequate power output of 55 kW at 5,500 rpm, was a clear priority for its developers. Despite its nominally small capacity, the direct-injection spark-ignition engine is easily capable of excellent performance (0-100 km/h in less than 12 seconds / top speed in excess of 170 km/h) and also makes for pleasurable driving.

In conjunction with the ASF body, very low drag coefficient, reduced rolling resistance and automated manual gearbox, the Al, design study’s average fuel consumption is around 40 percent lower than that of a conventional vehicle with a comparable amount of interior space and similar engine performance.

Transmission and suspension:

Automatic spontaneity

With such an efficient engine as its basis, the Al clearly needed a transmission concept that was entirely geared towards reduced fuel consumption. The automated manual gearbox with tiptronic control and automated power transmission is truly outstanding for its efficiency. A centrally controlled computer processes information such as engine speed, temperature, road speed and accelerator position to determine the optimum moment for a gearshift. An electro-hydraulic unit then actuates the clutch and performs the gearshift proper.

All this takes place swiftly, precisely and smoothly. No energy is lost as a result of slip, as happens on an automatic transmission with torque converter. In the automatic mode, the established benefits of the DSP Dynamic Shift Program are available.

If the driver wishes to decide himself when to change gear, he simply pushes the tiptronic control lever forward to shift up, or pulls it towards him to shift down a gear. A gear display in the instrument cluster indicates which gear is momentarily engaged. In combination with a lightweight, compact vehicle such as the Al2, the automated manual gearbox makes for very pleasurable driving.

The Al’s light but stable ASF body is the secret of its impressive handling. In conjunction with its low unsprung mass, the very high torsional rigidity and bending strength of the Alz body provide a sound basis for the vehicle suspension, improve its vibration and rolling properties and enhance steering precision.

The Audi Space Frame rests on McPherson spring struts at the front and a torsion beam axle at the rear. The front suspension, including the brake callipers, is of aluminium, as are the rear drum brakes. The 6J x 16 wheels are fitted with 175/55 R 16 tyres.

Environment and recycling:

Compatible, economical and pleasurable

Audi demonstrates through its Al, that the fully-fledged, comfortable compact vehicle of the future need not be any heavier than a present-day small car. Its weight saving has been achieved first and foremost with an engine that operates more efficiently and uses less fuel. The direct-injection principle has now evolved into an effective and highly promising technical concept for spark-ignition engines, once again opening up fresh scope for reducing fuel consumption.

The use of aluminium in automotive construction preserves natural resources and reduces the burden on the environment. This is because aluminium is largely produced from hydroelectric power. However, actual use of a vehicle – in other words, fuel consumption – accounts for the overwhelming portion of the energy used by a car throughout its lifecycle. The fuel saving achieved by the advanced technical features of the Al, would actually result in an overall energy saving after only 60,000 km. On a high-quality, durable car such along the lines of the Al concept, this means that the environment would likewise start to benefit at a relatively early stage in the vehicle’s useful life. Second time round, the energy balance for aluminium cars is even better: only a fraction of the energy used in the production of the primary material is needed to recycle aluminium to the same grade of purity.

Incorporating technology that is already established, the Audi Al is an enticing vision of a high-efficiency car that occupies only little road space, and a workable solution to the dilemma of how to combine mobility with responsibility.

Audi Alz – technical data

Status: September 1997

| Engine / electrics Engine type Number of valves per cylinder / compression ratio Bore x stroke in mm / displacement in cc Max. power output in KW (bhp) Max. torque in Nm Fuel injection system Exhaust emission control | Three-cylinder spark-ignition direct injection aluminium cylinder crankcase Five / 11.5 81 x 77.4 / 1196 55(75) / 5500 115/3000 Fuel Direct Injection FDI 3-way catalytic converter, DeNOx catalytic converter |

| Driveline / transmission Type of driveline Clutch Type of gearbox | Transverse engine with front-wheel drive Hydraulically operated single dry-plate clutch with asbestos-free lining Automated manual gearbox (5-speed), electro-hydraulic actuation of clutch and gear shift |

| Running gear / steering / brakes Front suspension Rear suspension Type of steering Brake system, front/rear Wheels / tyres | McPherson spring-strut front suspension in aluminium Torsion-beam rear suspension Maintenance-free rack and pinion with electro-hydraulic power assistance Diagonally split dual circuits with ABS/EDL Electronic Brake- Force Distribution EBD; front: disc brakes, aluminium brake callipers/ rear: aluminium alloy drum brakes 6J x 16 / 175/55 R 16 |

| Performance / consumption Top speed in km/h Acceleration 0-100 km/h in s Fuel grade Consumption of basic version in I/100 km (total, acc. to 93/116/EC) | Higher than 170 Less than 12 Super Plus unleaded 95/98 RON Approx. 4.3 |

| Weight Unladen weight (with basic specification) in kg Weight of design study in kg (with equipment as shown) Payload in kg | 750 810 425 |

| Body / dimensions Type of body Number of doors / seats Drag coefficient co Length (L103)/width excl. mirrors (W103)/height (H100) in mm Wheelbase (L101)/track, front/rear (W101/W102) in mm Luggage capacity acc. to VDA test blocks in I (V210) | Aluminium: Audi Space Frame ASF 5/4 0.25 3765 / 1620 / 1557 2406 / 1430 / 1426 350/ 840 with rear seat back folded + 180 beneath luggage compartment. floor |